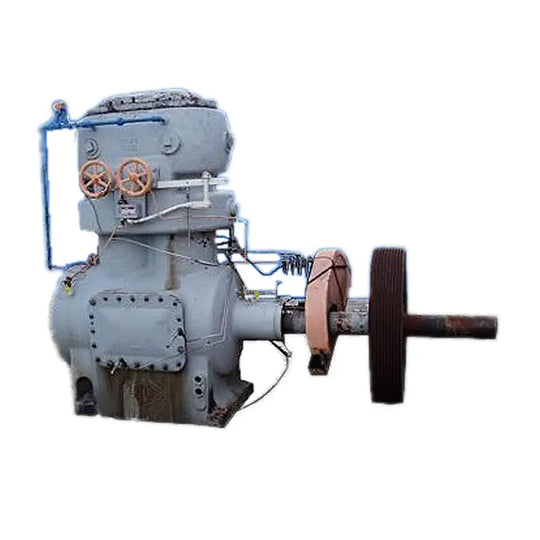

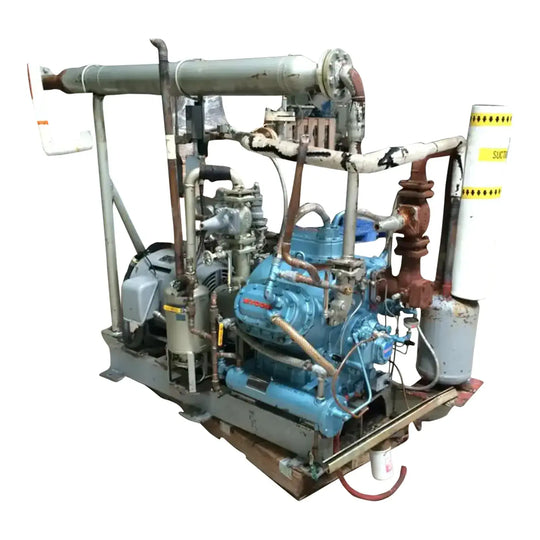

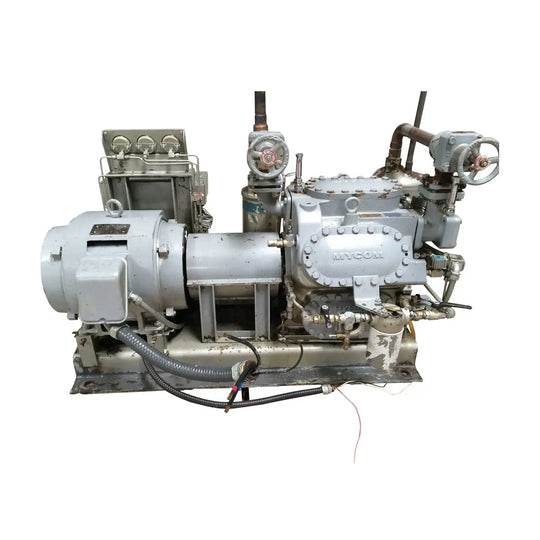

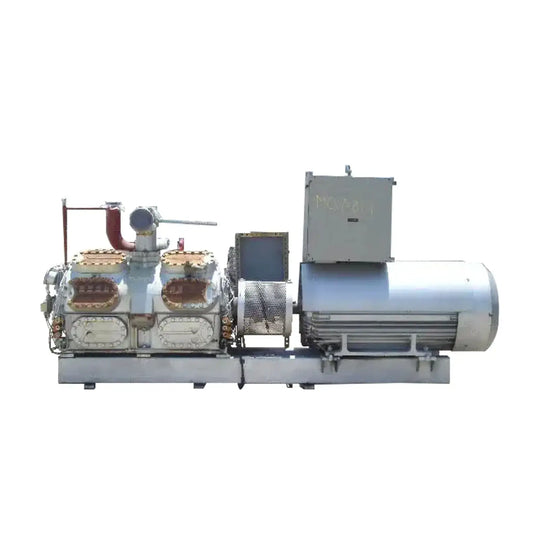

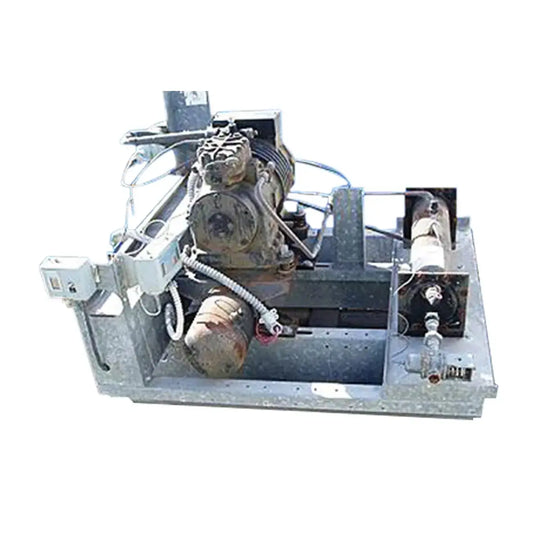

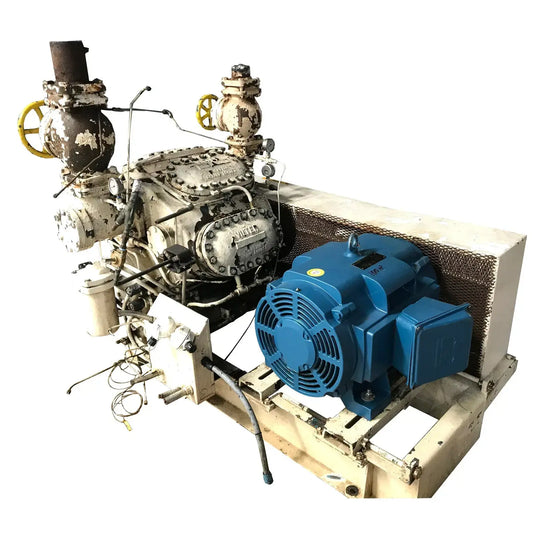

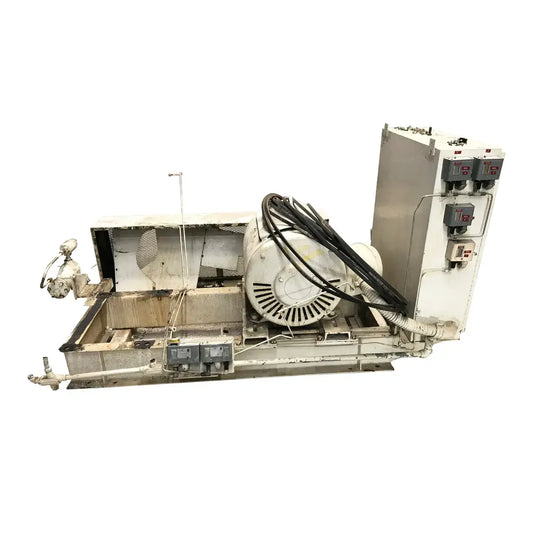

Shop Premium Used Reciprocating Compressors for Industrial Refrigeration

Genemco offers Reciprocating Compressors from top manufacturers

Shop Popular brands like Mycom, Frick, FES, and Vilter

- About

- FAQs

- ←

- →

A reciprocating compressor is a type of positive displacement compressor that uses a piston to compress the refrigerant. That's why these compressors are also known as "piston compressors." It operates on the principle of a reciprocating motion, allowing the piston to move back and forth within a cylinder to compress gas. It is commonly used in air conditioning and refrigeration systems for commercial and industrial applications.

A reciprocating compressor consists of a cylinder, a piston, and a crankshaft. The piston moves back and forth within the cylinder, compressing the refrigerant as it moves upward and expelling it as it moves downward. As the piston moves downward, it creates a vacuum in the cylinder, drawing in the gas. The upward movement compresses the gas in the chamber, increasing the pressure. The compressed gas is then released through a valve system in order to be used. The crankshaft converts the back-and-forth motion of the piston into rotary motion, which is used to drive the compressor. Overall, you can see that the mechanism of the compressor itself involves a series of components in order to operate efficiently. From the cylinder, piston, and the connecting rod to other parts, you'll find that each component plays a vital role in the compression process.

- The main components of reciprocating compressors include the following:

- Cylinder: The cylinder is the main component of the compressor and is designed to hold the gas or refrigerant.

- Piston: The piston is the component that moves back and forth within the cylinder and compresses the gas.

- Crankshaft: The crankshaft converts the back-and-forth motion of the piston into rotary motion.

- Connecting rod: The connecting rod connects the piston to the crankshaft.

- Bearings: The bearings support the crankshaft and allow it to turn smoothly.

- Seals: The seals prevent leakage and maintain proper compression.

- Lubrication system: The lubrication system provides lubrication to the bearings and other moving parts to reduce wear and improve efficiency.

- Valves: The valves play a role in the functionality of the compressors, allowing gas to enter the cylinder or allow for discharge pressure to exit. Valve operation allows for opening and closing to ensure proper flow direction and to prevent backflow.

- There are several advantages to using a reciprocating compressor. These machines offer a multitude of benefits that make them a popular choice for industrial applications. Check out some of their benefits below:

- High efficiency: Reciprocating compressors can operate at high compression ratios, resulting in high efficiency and low power consumption.

- Reliability: A reciprocating compressor is simple in design and has few moving parts, which makes it reliable and easy to maintain.

- Low maintenance: The compressor design allows for easy maintenance. They're easy to install and transport, and regular check-ups can keep these running smoothly for years.

- Minimal noise: This type of compressor is typically quieter than other types of compressors.

- Low cost: These compressors are relatively inexpensive to purchase and operate. Typically, you can find a reciprocating compressor for sale at a reasonable price point.

- Versatility: Whether you're in oil and gas, automotive, or manufacturing, these compressors can handle a wide range of applications.

As you can see, there are many reasons to invest in a compressor, from improved efficiency to versatility.

The two types of compressors have similar functions as far as producing compressed air. The main difference is the fact that a rotary screw compressor utilizes two meshing screws (rotors) that rotate next to each other. Air travels through these interlocking grooves as the spirals turn, and the air is compressed through the chambers. Rotary compressors are also typically designed to stand by themselves, and they don't last as long as a reciprocating compression system.

There are different types of reciprocating compression systems you'll want to understand. The first is the single-acting compressor. This operates by compressing gas in a single stroke of the piston, forcing it into a storage tank or through a discharge valve. There's also a double-acting compressor. This compresses gas during both upward and downward strokes of the piston. You'll also find that there's an oil-free compressor designed to eliminate the risk of oil contamination, typically in industries such as pharmaceuticals or food manufacturing. Our website is a great resource to learn more about the types of compressors available. For example, you can shop for bare compressors on our site today.

Inside the compressor, the piston moves back and forth, creating a powerful thrust that can generate the pressure needed for demanding tasks. This makes the reciprocating compression system ideal for tasks such as powering pneumatic tools, operating heavy machinery, and even filling up gas cylinders. Industries such as oil and gas, automotive, food and beverage manufacturing, and even pharmaceuticals can all utilize this type of equipment for better operational efficiency within their facility.

- When choosing reciprocating compressors on the Genemco website, you should consider several factors:

- Refrigerant type: Make sure the compressor is compatible with the type of refrigerant you are using.

- Capacity: Select a compressor with a capacity that meets the cooling requirements of your system.

- Operating conditions: Consider the operating temperature and pressure range of the compressor, as well as the ambient temperature and humidity of the environment it will be used in.

- Noise level: If noise levels are a concern, choose a compressor with a low noise level.

- Serviceability: Consider the ease of maintenance and availability of spare parts when selecting a compressor.

If you have questions regarding specific equipment, you can feel free to contact our team to assist you.