Shop Premium Used Plate Chillers & Freezers for Food Processing

Genemco offers used Plate Chillers and Plate Freezers for Optimal Cooling

Shop top brands like Turbo, RECO, and Amerio today!

- About

- FAQs

- ←

- →

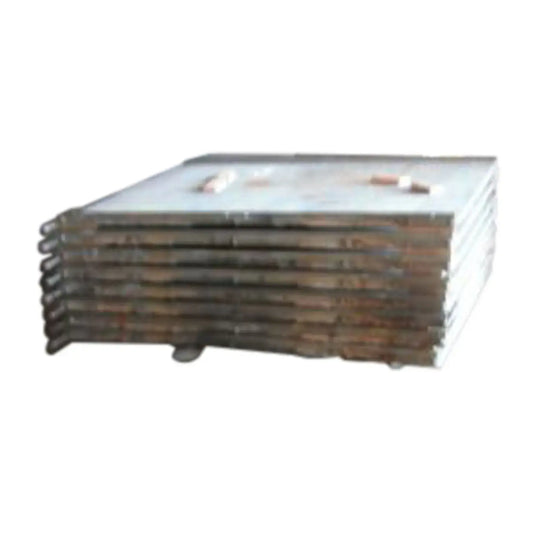

Plate chillers and freezers are innovative machines commonly used in commercial and industrial settings to cool or freeze food products rapidly. These devices utilize a series of stainless steel plates to achieve their cooling or freezing capabilities. As a professional in the industry, it's important to understand how these machines work to effectively utilize them in various applications.

An industrial plate chiller and freezer both operate on a similar principle. The food product to be cooled or frozen is placed between the chilled plates, which are cooled using a refrigeration system. In chillers, the refrigerant flows through the plates, absorbing heat from the product and lowering its temperature. On the other hand, in industrial plate freezers, the refrigerant flows within the plates, extracting heat from the product and freezing it.

The stainless steel cold plates in these machines have intricate patterns engraved on them, which greatly increase the surface area for heat transfer. This allows for efficient and rapid cooling or freezing of the product. The refrigerant circulating within the plates absorbs heat from the food product, causing it to cool down or freeze depending on the desired outcome.

The primary advantage of using plate chillers and freezers is their remarkable cooling efficiency. The large surface area of the metal plates allows for efficient heat transfer between the product being cooled and the refrigerant, resulting in rapid and uniform temperature reduction.

One of the key advantages of plate freezers and chillers is their compact size and high cooling capacity. These units occupy significantly less space compared to traditional refrigeration systems, making them ideal for applications where floor space is limited. Additionally, their ability to rapidly chill or freeze products enables faster production cycles, saving time and increasing productivity. This is particularly beneficial in industries such as food processing and pharmaceuticals, where quick temperature reduction is crucial to maintain product quality and safety.

Another advantage of these types of freezers and chillers is their energy efficiency. The design of these units promotes effective heat transfer, reducing the amount of energy required for cooling or freezing. As a result, businesses can save on energy costs while maintaining optimal product quality. These chillers and freezers are also easy to clean and maintain, minimizing disruption to production processes.

Plate chillers and freezers are versatile and widely used in various industries for different applications. These highly efficient machines utilize a plate heat exchanger to rapidly cool or freeze products, making them crucial in food processing, pharmaceutical, chemical, and beverage industries.

In the food industry, chillers and freezers find extensive use in freezing fruits, vegetables, meat, fish, poultry, and dairy products. Preservation of food items at low temperatures is essential to maintain product quality, prevent spoilage, and extend shelf life. Beverage production facilities also rely heavily on these chillers to cool beverages, such as juices, carbonated drinks, beer, and wine, during production and packaging. Rapid cooling is necessary to maintain the flavor profile, carbonation, and overall quality of the beverages.

Pharmaceutical companies can utilize plate freezers and chillers for various purposes, such as fast cooling of medications, vaccines, and blood products. These machines aid in keeping pharmaceutical products at controlled temperatures, preventing degradation, and maintaining their effectiveness. Furthermore, chillers are employed in cooling pharmaceutical manufacturing equipment and cool water used in the production process.

In the chemical industry, plate chillers are used for cooling chemical compounds or ingredients. This helps in maintaining the quality and stability of chemical products, preventing unwanted reactions or degradation due to excessive heat.

No matter what industry you are in or what your specific needs may be for chillers and freezers, Genemco can provide you with the perfect solution. As a leading provider of quality used industrial cooling and freezing equipment, we offer an extensive selection from top manufacturers such as Turbo, RECO, and Amerio. Whether you require a single chiller or freezer or a complete system, you can trust that we have it in our inventory.