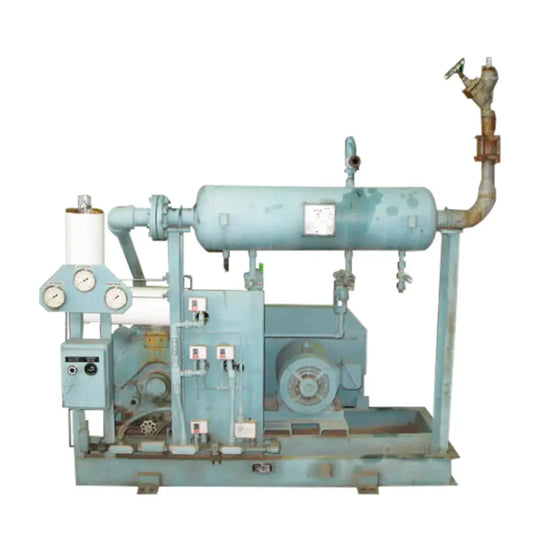

Reciprocating Compressor Packages

Genemco offers the top Reciprocating Compressors in North America

Shop from top brands like GEA, Vilter, and Mycom

- FAQs

- ←

- →

Frequently Asked Questions

Reciprocating compressor packages are designed for seamless integration into refrigeration systems. They help optimize the overall performance of refrigeration systems due to their compact design and pre-engineered components. This ensures efficient operation and minimizes installation time.

An industrial reciprocating compressor is a device that uses a piston to compress refrigerant gases to maintain low temperatures in various applications. Moving refrigerant gas within a closed system creates the necessary conditions for cooling.

Reciprocating compressors play a crucial role in food processing. They help maintain optimal temperatures in cold storage facilities, freezing units, and other processing areas, ensuring the quality and safety of food products.

Yes, reciprocating compressors are versatile and can be adapted for low- and high-pressure applications. Their design allows adjustments to accommodate different pressure requirements, making them suitable for various industrial processes.

The crankshaft converts the linear motion of the pistons into a rotary motion to generate continuous compression cycles. As the pistons move up and down within the cylinder, the crankshaft translates the reciprocating motion into rotary motion to drive the compressor's other components and the motor. This rotary motion is necessary to compress and circulate refrigerant gases throughout the system.

The crankshaft rotates, causing the pistons to move up and down in the cylinder. On the downward stroke, the piston creates a low-pressure zone, allowing the refrigerant to enter the cylinder. On the upward stroke, the gas compresses, and pressure increases. The high-pressure gas gets discharged into the system, contributing to the cooling process. The design and efficiency of the piston are critical for achieving the desired compression ratios and maintaining temperature control in food manufacturing applications.

Reciprocating compressor packages provide a turnkey solution with pre-assembled components, streamlining the installation process. This saves time and ensures compatibility among components, reducing the risk of operational issues.

The main difference between reciprocating and other compressors is the compression mechanism. Compared to reciprocating compressors, rotary screw compressors typically use rotating elements or screws to achieve compression. Reciprocating compressors are known for their efficiency and suitability.

Reciprocating compressors are efficient for smaller to medium-sized systems. Centrifugal compressors utilize a rotating impeller, making them preferable for larger applications with consistent refrigeration demands. Reciprocating compressors excel in simplicity and adaptability to fluctuating loads, while centrifugal compressors, though more complex, are efficient in continuous operations.

Top Sellers

View all