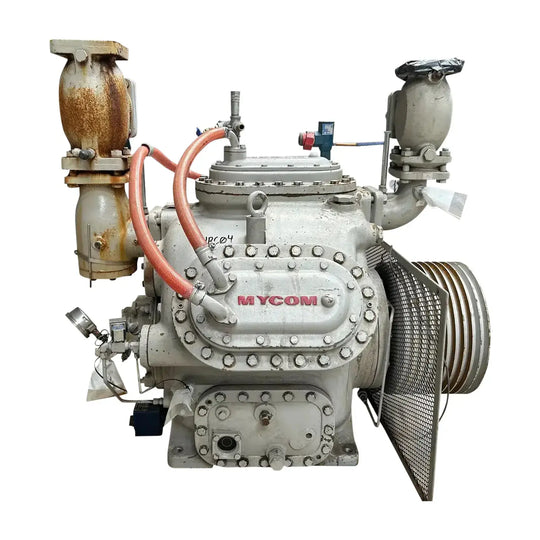

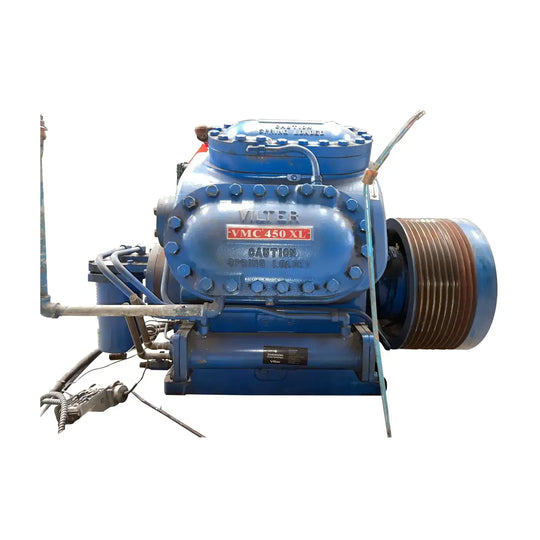

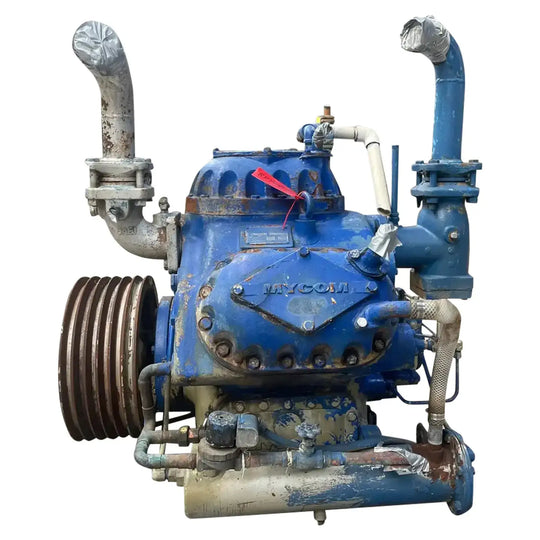

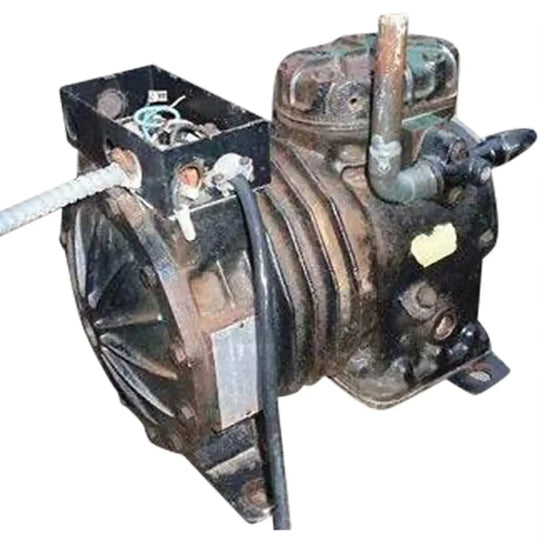

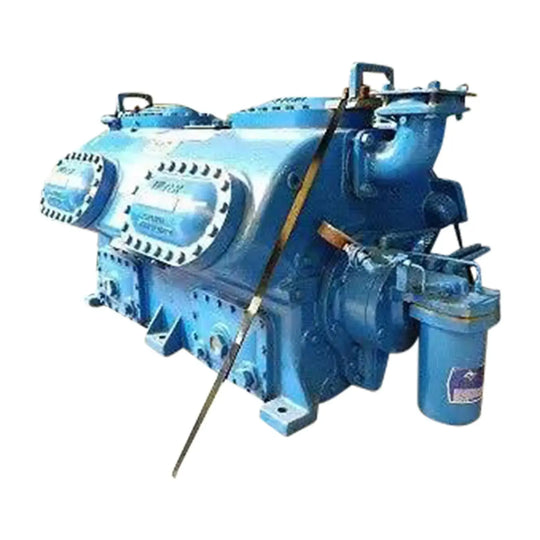

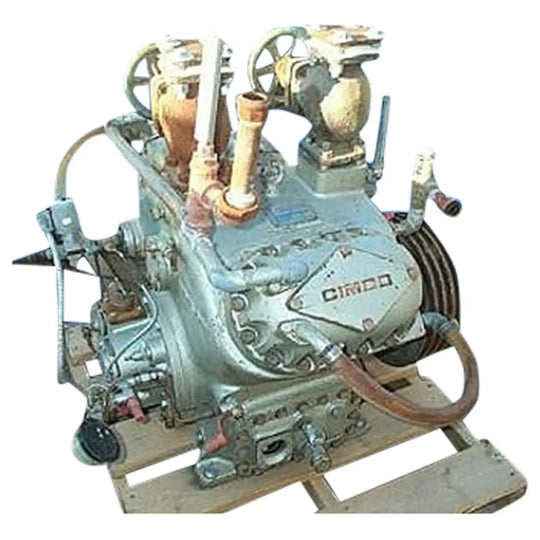

Shop Premium Used Bare Reciprocating Compressors for System Rebuilds

16-cylinder, 12-cylinder, 8-cylinder, and 4-cylinder reciprocating compressors

Shop top manufacturers like Vilter, Mycom, and Howe

- About

- FAQs

- ←

- →

Frequently Asked Questions

A bare reciprocating compressor utilizes a piston-cylinder arrangement to compress refrigerant gases. Unlike other compressor types, they operate without additional components such as condensers or evaporators, making them suitable for specific industrial refrigeration applications where a more straightforward design is preferred.

Reciprocating compressors offer high efficiency, reliability, and durability, making them well-suited for demanding applications in the food processing industry. They ensure consistent temperature control and consistent operation due to their unique design, a necessity for preserving food quality.

The crankshaft is crucial in converting the reciprocating motion of the pistons into rotary motion in bare reciprocating compressors. Because piston reciprocating motion is inherently linear within the cylinder, the crankshaft creates a circular motion that drives the compressor's rotation. This rotary motion is essential for the continuous operation of the compressor.

As the crankshaft rotates, it imparts rotational energy to the compressor's components, including the pistons and other associated reciprocating compressor parts. This drive mechanism is critical for maintaining a consistent and reliable compression and expansion cycle.

Pistons compress gases during compression strokes, moving up and down within the cylinder. This allows for the transfer of heat and the creation of a high-pressure refrigerant that gets circulated throughout the system.

Bare reciprocating compressors offer high efficiency, durability, and ease of maintenance, making them ideal for various industrial refrigeration applications.

The versatile reciprocating compressor is widely used in various applications, including cold storage, meat and poultry processing, dairy production, and beverage manufacturing. They can handle varying refrigeration loads, making them suitable for different stages of food processing.

Suction and discharge regulate the flow of refrigerant gases into and out of the cylinder. Suction valves allow the entry of low-pressure refrigerant gas during the suction stroke, while discharge valves enable the release of high-pressure gas during the compression stroke, contributing to the overall efficiency of the compression process.

Regular inspections and replacement of worn valves are essential for proper sealing and efficient operation. Proper valve maintenance and function contribute to the reciprocating compressor's reliability and longevity.

Piston rings prevent refrigerant gases from leaking during compression. Forming a seal between the piston and the cylinder walls is crucial in maintaining the efficiency and performance of the compressor.

Packages are comprehensive systems that include a compressor and associated components such as motors, controls, and other necessary accessories. These packages offer a turnkey solution for industrial refrigeration needs, simplifying the installation process.

At Genemco, we pride ourselves on collaborating with esteemed refrigeration brands such as GEA, Vilter, and Mycom. Our ongoing partnerships with industry leaders further underscore our commitment to excellence. Each bare reciprocating compressor package undergoes comprehensive testing and stringent quality assurance procedures, adhering to industry standards and our valued customers' high expectations. To discover firsthand experiences of businesses akin to yours, explore testimonials about working with us.

Top Sellers

View all