Cooling Towers

Shop for a used cooling tower system to elevate your cooling process and distribution system.

We offer cooling towers from top brands like Evapco, BAC, Marley.

- FAQs

- ←

- →

Frequently Asked Questions

Cooling towers serve as indispensable components in various industrial and commercial systems, including industrial facilities, HVAC systems, and natural gas processing plants. Used in these contexts, towers play a pivotal role in the cooling process, which involves the intake of hot water, subsequent cooling to lower temperatures, and the release of the cooled water.

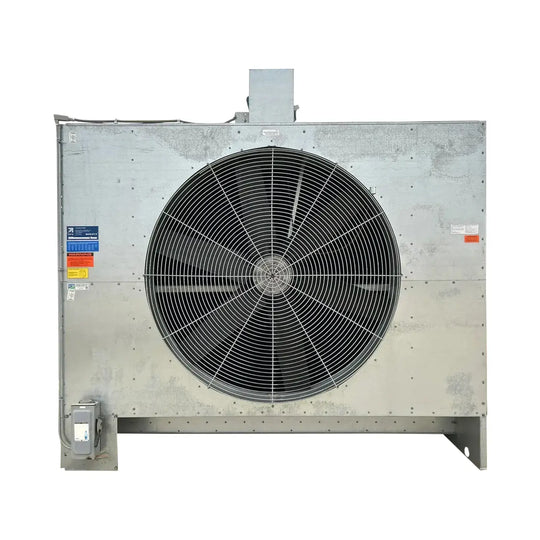

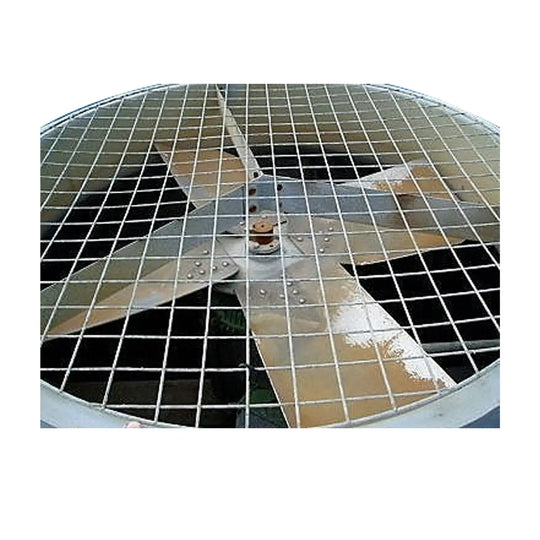

The amount of cooling provided by the tower is measured in nominal tons. Nominal tons refer to the amount of heat removed by the tower. The nominal tonnage is determined by the rate at which it can circulate and absorb heat from the warm water. This rate is determined by the size of the tower fan, the area of the tower, and the airflow and water flow rates. The nominal ton rating of a cooler tower is a useful tool for specifying the size and type of tower to meet certain evaporative cooling requirements of various industrial processes.

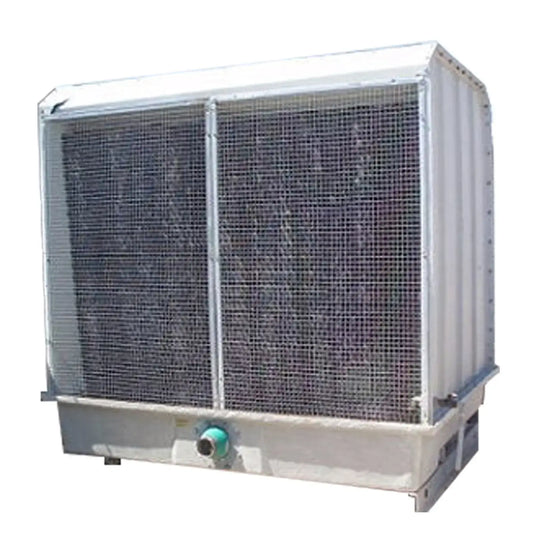

These towers play a crucial role in cooling hot water and various liquids. They are substantial structures that harness the principles of evaporative cooling to lower the temperature of these liquids. These towers come in different variations, constructed from materials like stainless steel or fiberglass. Industrial tower systems find application across a spectrum of industries and industrial processes, including power plants, water treatment facilities, food processing plants, and various other industrial operations. In particular, using corrosion-resistant stainless steel in these towers is indispensable in industrial settings.

Fiberglass towers are an excellent option for industrial applications where weight is a concern, as it's light and cost-effective. These towers can be used for cooling process water, condenser water, engine cooling water, and other fluids.

Cooling towers are a vital part of many industrial processes and cooling systems, providing highly efficient and cost-effective methods of controlling water temperature in a wide range of industrial applications. The large fans help control the cooling process and tower temperatures and are essential for ensuring a safe and productive industrial environment.

Buying used industrial cooling tower systems offers several benefits for businesses. Used towers are typically more affordable than buying new ones. This can save businesses money and is an attractive option for those with budget constraints or those looking to reduce capital expenses. Buying well-maintained and reliable equipment can help your industrial processes continue without interruptions.

You can also often upgrade or retrofit used towers with modern components and technologies to improve efficiency and performance. This allows you to still save money rather than buying new equipment.

Poor water quality can lead to scaling, corrosion, and biological growth of bacteria within the tower. This reduces heat transfer efficiency, can damage tower components, and increases maintenance frequency. Proper water treatment and filtration are essential. Water quality is a critical factor in the efficient operation, longevity, and maintenance of towers.

- When selecting a location for an industrial refrigeration tower, factors to consider include:

- Proximity to the equipment needing cooling to minimize piping and energy losses

- Adequate space for the tower and airflow

- Accessibility for maintenance and inspections

- Compliance with local environmental and safety regulations

- Prevailing wind direction to avoid air recirculation and interference with other equipment

Open cooling towers come in direct contact with the atmosphere. Closed towers use a heat exchanger to separate process fluid from the outside air; this prevents direct contact. Closed towers in industrial refrigeration are often preferred when maintaining water quality and preventing contamination are critical. Open towers are used more frequently when preventing contamination and maintaining water quality are not major concerns.

Yes, they can be integrated with heat recovery systems to help capture waste heat and improve efficiency. In many industrial systems, the extracted heat is often wasted. But integrated with recovery systems can help repurpose the heat for space heating or preheating water. This not only improves the energy efficiency of the refrigeration system but also reduces the overall energy consumption of the facility.

Properly designed and maintained towers play a crucial role in improving energy efficiency in industrial refrigeration systems. Removing excess heat reduces the workload on other equipment like chillers or condensers. Equipment can operate more efficiently and consume less energy, leading to energy savings.

Genemco has the world's most extensive inventory of pre-owned industrial refrigeration and food processing equipment. With 175,000+ square feet of warehouse space and 30 acres of inventory at our disposal, we stand out for having a substantial on-hand selection.

Because we own our equipment, we can bypass lead times and eliminate unnecessary middlemen, ensuring faster delivery and lower costs than competitors.

Our dedicated team of bilingual experts is committed to helping you find the cooling towers to meet your production requirements while staying within your budget. With Genemco, you're not just buying equipment; you're gaining a trusted partner in your industrial refrigeration needs.

Top Sellers

View all