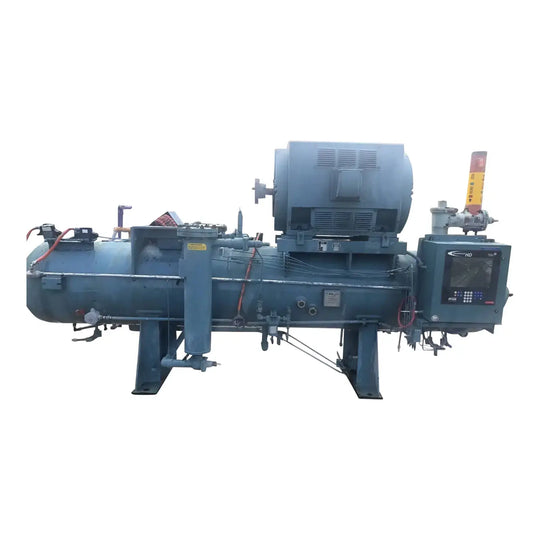

Shop Premium Used Compressor Packages Without Screws for System Rebuilds

Genemco offers screw compressor parts and full packages.

Find all the product details and individual compressor parts for sale from leading manufacturers.

- About

- FAQs

Screw compressor parts use two interlocking helical rotors to compress refrigerant gas. As the rotors rotate, they trap and compress the refrigerant, creating a continuous flow of compressed gas. This compressed gas is then used in the refrigeration system to remove heat from the environment.

Screw compressors offer high efficiency, low maintenance requirements, and a compact design. They're suitable for heavy-duty industrial applications and provide a consistent and reliable cooling solution for food processing facilities.

Screw compressor packages are designed to work with various refrigerants, including ammonia (R717) and halocarbon (freon).

Screw compressors are known for their energy efficiency and precise temperature control. Their flexibility allows them to operate at varying capacities to match cooling load requirements to minimize energy consumption, resulting in cost savings for food manufacturing facilities.

Yes, screw compressor packages are available in a range of sizes and capacities, making them suitable for both small and large-scale food manufacturing operations. The scalability of these packages allows for customization based on the specific refrigeration needs of the facility.

Yes, rotary screw compressors are available in both oil-injected and oil-free versions. Oil-injected compressors are common for industrial applications, while oil-free compressors are preferred when oil contamination is a concern.

Rotary screw compressors offer high efficiency, reliability, and quiet operation. They're known for their continuous duty cycle and lower maintenance requirements.

Unlike reciprocating compressors that use pistons, rotary screw systems operate with rotating helical screws. This design results in smoother and more continuous compression, reducing pulsation and vibration.

The main screw compressor parts include the rotor pair, housing or casing, inlet and discharge ports, and other essential elements such as bearings, seals, and lubrication systems.

The rotor pair, consisting of male and female helical rotors, is the primary component responsible for compressing the refrigerant gas. As the rotors intermesh, they create a continuous compression process, moving the refrigerant from the inlet to the discharge port.

The housing surrounds the rotor pair and forms the compression chamber, playing a crucial role in maintaining the proper alignment of rotors creating the right conditions for efficient refrigerant compression.

The inlet port allows refrigerant gas to enter the compression chamber while the discharge valve releases compressed gas. Proper sizing and control of these ports are essential for the operation of the screw compressor.

Top Sellers

View all