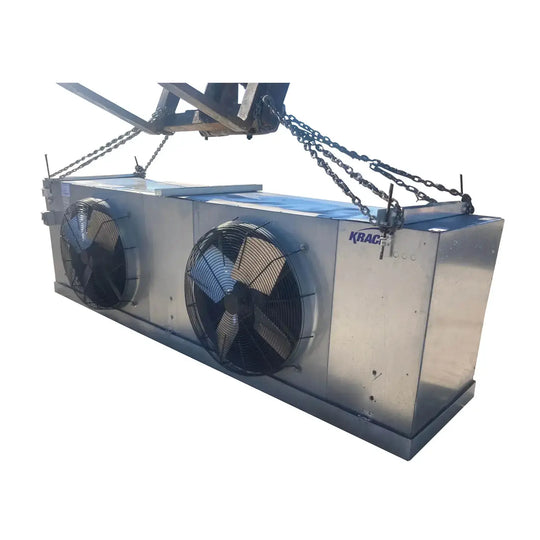

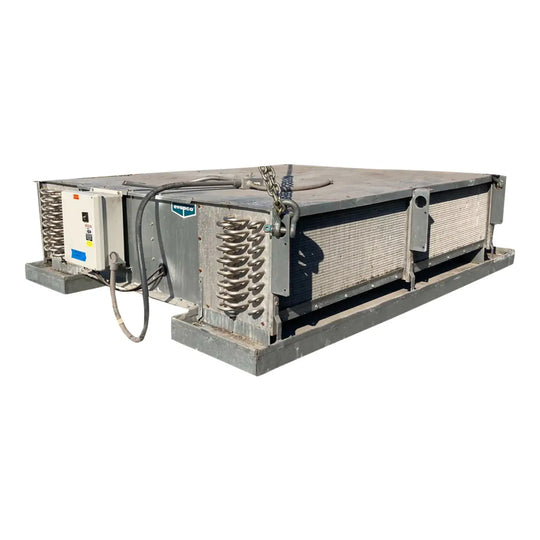

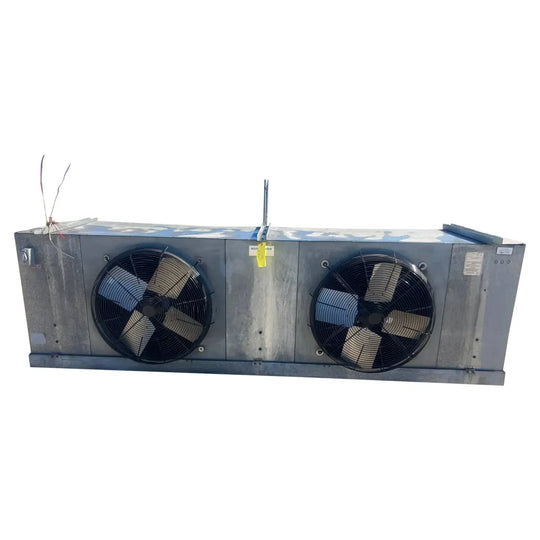

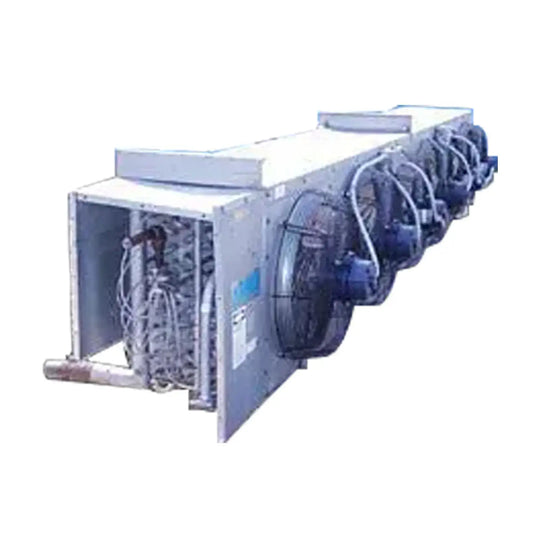

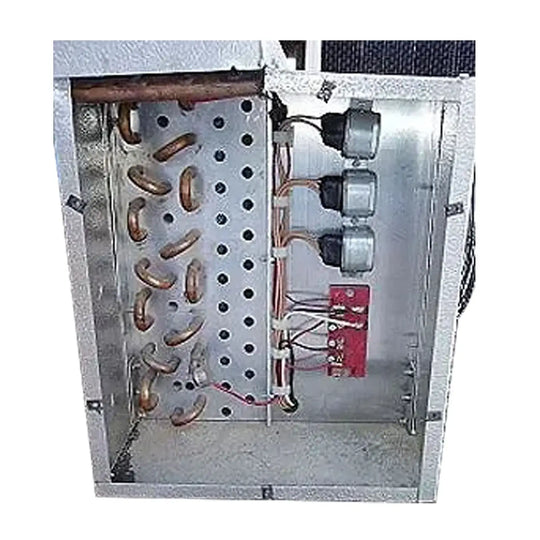

Medium-Temperature Evaporator Coils

Genemco sells Evap Coils from Evapco, Vilter, Krack, Frick, Imeco and all the leading Manufacturers.

Browse our full collection of Industrial Evaporator Coils to amplify your refrigerant systems.

- FAQs

- ←

- →

In industrial processing, a manufacturer will typically use evaporator coils for food and beverage processing, chemical manufacturing, pharmaceutical production, and many other functions. These coils are designed to remove heat from the process fluid or air which assists in cooling or freezing the substances that are being processed. The heat transfer allows the coils to absorb heat and reduce the temperature of the substance or product inside the system.

When it comes to the refrigeration system, the coils are found in the evaporator where the refrigerant undergoes a phase change from liquid to gas. This leads to the cooling effect necessary to keep a product cool.

When it comes to industrial evap coils, maintaining the correct temperature is essential for optimal performance and energy efficiency. The temperature of the evap coil will depend on whether it's used for refrigeration equipment, HVAC, or other applications. The ideal temperature is typically between 35 degrees and 45 degrees Fahrenheit. These temperatures are necessary because the coil is a heat exchanger. To maintain these temperatures, the coils must have reliable airflow and heat exchanger capabilities.

Low-temperature models are specifically designed to handle colder temperatures for products. These are suitable for refrigeration applications, such as walk-in freezers or ice cream cabinets. The coils are built with larger surface areas to maximize heat transfer and ensure efficient cooling.

Meanwhile, medium-temperature coils are specifically designed for moderately cold temperatures. This can include commercial refrigeration such as coolers and display cases for grocery stores. The coils operate at a higher temperature than the low-temperature models. The moderate-temperature model has optimized surface areas and tube configurations to balance cooling and energy consumption. The best coil temp unit will entirely depend on the function.

If you have the experience and technical knowledge, you can replace it yourself. Overall, it's recommended to have a professional technician replace the components because the process will include handling refrigerant, using specialized tools and equipment, as well as understanding electrical safety when handling the unit. When shopping for these components, it's also essential to use a brand that is of high quality to ensure its durability.

Industrial evaporator coils should be thoroughly cleaned, especially considering that it's often used for food processing and commercial refrigeration. Medium-temperature evaporator coils can accumulate dirt, dust, bacteria, and other debris which can compromise the performance and lead to various issues. The frequency of cleaning will depend on a few factors, such as the environment in which the refrigeration system operates, the types of products being stored, and any other contaminants. Consult a professional at Genemco to ask about optimal performance and increasing the longevity of your unit. Shop from some of the best brands on our site, including Frick, Evapco, and Krack.

Top Sellers

View all